Manylion Cyflym

Cyflwr: Newydd

Foltedd: 220

Pwer Graddedig: 1000W

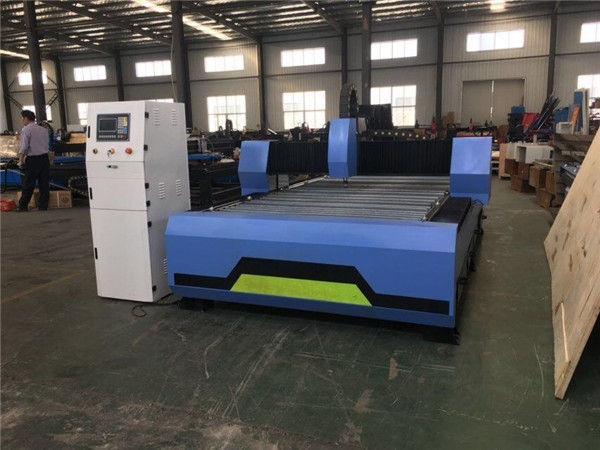

Dimensiwn (L * W * H): 3305MM * 780MM * 2110

Pwysau: 600KG

Ardystiad: ccc

Gwarant: 1 flwyddyn

Gwasanaeth Ôl-werthu a Ddarperir: Peirianwyr ar gael i wasanaethu peiriannau dramor

brand: nakeen

modd torri: plasma

trwch torri: 0.1-16mm

cnc ai peidio: ie

ardal dorri: 1300 * 2500

gwybodaeth ffeil: USB

MOQ: 1SET

PACIO: ACHOS PLYWOOD

Deunydd TORRI: metel .alloy metel .aluminium

rheoli uchder: rheolaeth uchder foltedd arc a thrydan

Mantais cynnyrch

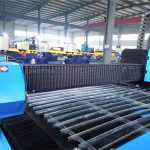

Gyriant 1.Bilateral, gweithrediad sefydlog

Cywirdeb uchel, effaith dda

3. Uchder foltedd arc (THC)

4.Gall gosod dyfais chwistrellu dŵr, lleihau'r dadffurfiad thermol

Torrodd 5.Can ddur carbon, dur gwrthstaen, copr, alwminiwm a metelau anfferrus eraill

6. Gweithrediad a chynnal a chadw syml ac ati.

Nodweddion a manteision

1. Cymharwch â'r torri plasma, mae ganddo'r toriad manwl uchel ar gyfer gwahanol fathau o ddeunyddiau metel, fel torri dur gwrthstaen, dur carbon, dur aloi, dur gwanwyn, alwminiwm, copr, arian, titaniwm a deunyddiau metel eraill o dan 6 mm.

2. Cymharwch â'r CC, a all dorri unrhyw broses a siâp cymhleth. Dim sŵn a dim angen agor unrhyw fowldiau o gwbl.

3. Cymharwch â thorri llinellol, sydd â chyflymder llawer cyflymach, 100 gwaith yn uwch nag ef.

4. Sgriw plwm dwbl i yrru, Parth bach wedi'i effeithio ar wres, sefydlogrwydd dimensiwn da. Slot laser â fflat a golygus, heb broses ddiweddarach

5. Cymhareb perfformiad / pris uchel: dim ond 1/8 o'r peiriant torri laser CO2 tebyg yw'r pris a 2/5 o'r NC Punch cyfatebol

6. Cost defnydd isel: dim ond USD2 yr awr sef 1 / 8-1 / 10 o'r peiriant torri laser CO2 tebyg (USD22-USD35 yr awr)

7. Cost cynnal a chadw isel isel: dim ond 1 / 10-1 / 15 o'r peiriant torri laser CO2 tebyg ac 1 / 3-1 / 4 yr NC Punch cyfatebol

8. Perfformiad cyson: fel cyfarpar laser aeddfed, mae peiriant torri laser YAG yn addas ar gyfer y mwyafrif o ddiwydiant gweithgynhyrchu a phrosesu metel.

Paramedrau technegol

| 1 | Torri siâp | unrhyw siapiau |

| 2 | Dimensiwn Arddangos LCD | 7.0Inches |

| 3 | Lled Torri Effeithiol (echel X) | 1300mm |

| 4 | Hyd Torri Effeithiol (echel Y) | 2500mm |

| 5 | Hyd Trawst Trawst | 1800mm |

| 6 | Hyd Rheilffordd Hydredol | 3000mm |

| 7 | Cyflymder Torri | 0-8000mm y funud |

| 8 | Trwch Torri Plasma | 2--20mm (Yn dibynnu ar gapasiti ffynhonnell pŵer plasma) |

| 9 | corff codi | 1set |

| 10 | Modd Gyrru | gyriant dwyochrog |

| 11 | Modd Torri | plasma |

| 12 | Dyfais tanio | Dyfais tanio awto |

| 13 | Dyfais rheoleiddio uchder | Uchder foltedd arc |

| 14 | Trosglwyddo ffeiliau | Trosglwyddo USB |

| 15 | Meddalwedd nythu | Safon Fastcam |

| 16 | Trosglwyddo ffeiliau | USB |

| 17 | Dimensiwn Arddangos LCD | Lliw 7 " |

| 18 | Ffynhonnell Pwer Plasma | Hypertherm PowerMAX65 / 85/1650 neu arall |

| 19 | Aer Plasma | Dim ond gwasgu Aer |

| 20 | Pwysedd Aer Plasma | Max. 0.8Mpa |

| 21 | Torri manwl gywirdeb | ± 0.5mm Safon genedlaethol JB / T10045.3-99 |

| 22 | Rheoli cywirdeb | ± 0.01mm |

| 23 | Foltedd / Amledd Cyflenwad Pwer | 220V 50HZ |

| 24 | Cyflenwad Pŵer Graddedig | 1000W |

| 25 | Tymheredd Gweithio | -10 ° C-60 ° C. Lleithder Cymharol, 0-95%. |

System reoli a chyflwyniad meddalwedd

Cyfansoddir y system reoli hon gan y cyfrifiadur diwydiannol, cerdyn rheoli canolfan, arddangosiad rheolydd cyflenwad pŵer, meddalwedd rheoli proffesiynol. Mae'r PC wedi'i osod yn y blwch rheoli, mae'r cerdyn rheoli canolfan yn derbyn yr archebion o'r feddalwedd ac yn ei weithredu. Trwy arddangos rheolydd y cyflenwad pŵer, rydyn ni'n goleuo'r lampau Xe, yn addasu'r paramedrau torri fel cerrynt, amledd, lled pluse sy'n cyd-fynd â gwahanol ddefnyddiau a thrwch plât. A thrwy'r meddalwedd rheoli, rydyn ni'n gosod y ffeil dorri, yn ychwanegu'r llinell arweiniol, yn rhoi iawndal i kerf, yn trwsio'r safle torri ac ati.